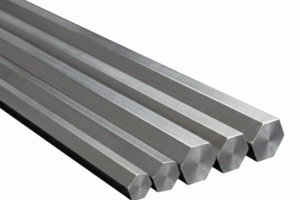

A hex bar plays a major role in modern machining work. Many manufacturers prefer a stainless steel hex bar because it offers strength, accuracy, and clean finishes. Since machining demands tight tolerances, the right hex bar helps reduce errors and material waste. As a result, stainless steel hex bars have become a reliable choice across industries.

In this blog, you will learn why a stainless steel hex bar works so well for machining applications and how it improves efficiency and performance.

Why a Hex Bar Shape Matters in Machining

The hex bar shape offers clear benefits during machining. First, it provides flat surfaces. These surfaces allow a strong grip in chucks and fixtures. Therefore, the hex bar stays stable during turning and milling.

Also, a hex bar reduces the need for extra machining steps. Since it already has flat faces, machinists save time on shaping. As a result, production becomes faster and more cost-effective.

Stainless Steel Hex Bar Material Benefits

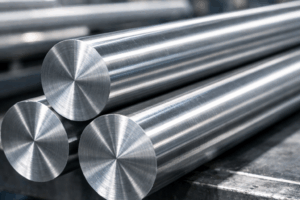

A stainless steel hex bar combines the strength of steel with excellent corrosion resistance. Because of this balance, it suits both indoor and harsh environments.

Strength and Durability of a Hex Bar

A stainless steel hex bar offers high tensile strength. It handles cutting forces well. Therefore, tools face less vibration during machining. This leads to better surface finish and longer tool life.

Moreover, the consistent structure of a hex bar ensures uniform performance. Machinists can expect predictable results across batches.

Corrosion Resistance Improves Machining Results

Corrosion can affect accuracy and finish. However, a stainless steel hex bar resists rust and oxidation. Because of this, the material stays clean during storage and machining.

In addition, corrosion resistance reduces the need for surface rework. This saves time and lowers overall production costs.

Machinability of Stainless Steel Hex Bar

Machinability depends on material composition and consistency. A high-quality stainless steel hex bar machines smoothly when it meets proper standards.

Consistent Dimensions in Hex Bar Production

Dimensional accuracy matters in machining. A precision-made hex bar maintains tight tolerances. Therefore, machinists can set up machines faster and reduce adjustments.

Also, consistent size helps automate processes. CNC machines perform better when the hex bar remains uniform from end to end.

Surface Finish and Tool Wear

A clean surface finish on a stainless steel hex bar reduces friction. As a result, cutting tools last longer. This improves productivity and lowers tooling costs.

Furthermore, smooth surfaces reduce heat buildup. This supports stable machining conditions.

Grades of Stainless Steel Hex Bar for Machining

Different machining tasks require different grades. Choosing the right hex bar grade improves efficiency.

Common grades like 303 offer enhanced machinability. Grades such as 304 and 316 provide higher corrosion resistance. Therefore, manufacturers select grades based on application needs.

Because stainless steel hex bars come in many grades, they suit automotive, engineering, and industrial components.

Applications That Benefit from Stainless Steel Hex Bar

Many industries rely on a stainless steel hex bar for precision parts. These include fasteners, shafts, bushings, and connectors.

The hex bar shape supports accurate threading and turning. Therefore, it works well for high-volume machining tasks. Also, its strength ensures long service life in finished components.

How to Choose the Right Hex Bar for Machining

To select the right hex bar, consider grade, size, and tolerance. Also, review surface finish and straightness. These factors affect machining speed and accuracy.

In addition, sourcing from a trusted supplier ensures consistent quality. This helps avoid downtime and material rejection.

Ambica Steels Hex Bars for Machining Applications

Ambica Steels manufactures high-quality stainless steel hex bars designed for machining precision. The hex bars feature uniform dimensions, clean surface finish, and reliable mechanical properties. Because of strict quality checks, machinists achieve smooth cutting and consistent results.

Ambica Steels hex bars support CNC and conventional machining. They suit demanding applications where accuracy and repeatability matter. As a result, manufacturers trust them for critical components.

By choosing the right hex bar and supplier, manufacturers improve productivity and part quality. In the long run, a reliable stainless steel hex bar supports efficient and cost-effective machining.