Since the beginning of the industrial revolution, humankind has been thriving daily to produce precise and superior quality products. The aforementioned situation is with steel manufacturing industries which, resulted in the invention of precision bars. Precision round bars have revolutionized industries, offering a superior alternative to ground and polished

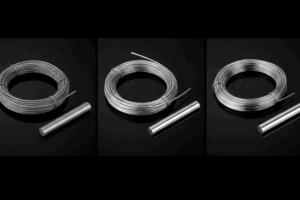

Precision Round Bars, as the name suggests, are bars manufactured with a high degree of accuracy and precision. Close dimensional and straightness tolerances, strength, smooth surface finish (lower surface roughness), roundness are some primary characteristic features that make precision round bars fit for its purpose in industries. The method employed in manufacturing these bars helps in achieving characteristic properties and thereby making precision round bars more reliable, efficient, operative, and high performing.

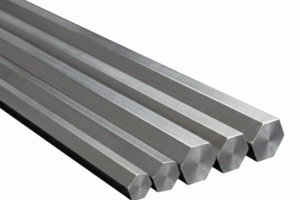

Stainless Steel Precision Bars

Stainless steel precision bars offer higher strength, toughness, hardness, corrosion resistance, thereby making them more popular among all industries. Adding to advantages, stainless steel bars can easily withstand extremely harsh climatic conditions. Stainless steel precision bars can be customized in various grades, sizes, lengths, shapes, and surface finishes.

While manufacturing or transporting precision bars, the following attributes must be taken into consideration. These attributes differ precision bars from others:

VIBRATIONS:

Since heavy machinery uses precision round bars, maintaining a high degree of straightness in them is essential. This ensures minimal vibration during operation. Excessive vibration can reduce machine efficiency by generating excess heat or damaging parts of the machine. To achieve the narrow straightness tolerance (about 0.25 mm/mtr.), the bars pass through straightening machines until they reach the desired straightness.

STRENGTH OF PRECISION ROUND BAR:

As precision round bars find their application in machines subjected to heavy load, pressure, and stress under extreme climatic conditions, therefore it is highly essential that the manufactured bar has strength (Tensile and Yield strength) suitable for its application. The strength of these bars depends on the chemical composition and heat treatment technique (Annealed, Solution Annealed, Quench and Tempered, Hardened and Tempered, Quenched, and Double Tempered) subjected during manufacturing. The strength varies from grade to grade.

DIAMETER OF PRECISION ROUND BAR:

The principal characteristic of precision round bars be close dimensional tolerances, which are achieved by carefully machining (grinding) the bars several times till desired tolerance is achieved. Close dimensional tolerance is highly essential to avoid damage to machinery or bar itself, which is in working condition. To obtain maximum machine output, it is also essential that the bar used should be free from ovality and lobbing.

ROUGHNESS OF PRECISION ROUND BAR:

To minimize frictional losses between the bar and the machine, manufacturers supply precision bars with a lower degree of surface roughness. They reduce the surface roughness of the bars by passing them through the polishing unit several times until they achieve the desired surface finish (Ra-0.2 um/12 RMS min).

SHIPPING:

To preserve surface condition, close dimensional tolerances, and straightness, manufacturers carefully ship precision bars to the customer. They take considerable care during packaging and dispatch. They pack precision bars in a variety of protective materials, use rings, and place them in plywood boxes to ensure safety during transportation.

APPLICATIONS:

Precision round bars due to its characteristics attributes have an extensive amount of applications. Some of them are:

- Pump Shaft Manufacturing

- Boat Shaft Manufacturing

- Oil and Gas Industries

- Petrochemical Industries

- Automobile Industries for Piston Rod, Cylinder Shaft, and other components.

- Valve Shaft

- Hydraulic/Pneumatic Piston Shaft

- Chrome Plating Quality Bars

- Bearing Sized Bars

- In Precision Machined parts