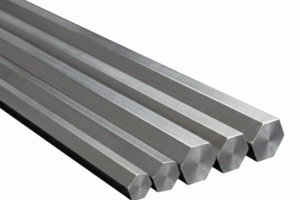

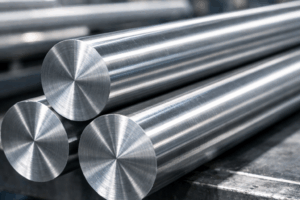

Precision, strength, and surface finish are the defining qualities of stainless steel bright bars. These properties are not achieved through ordinary rolling processes but through carefully controlled cold-finishing techniques. A professional stainless steel bright round bar manufacturer in India follows a detailed production procedure to ensure consistent quality, dimensional accuracy, and excellent performance across industries.

This guide explains the complete bright bar steel manufacturing procedure, from raw material selection to final inspection.

What is Bright Bar Steel?

Before understanding the procedure, it is important to know what makes a bright bar different from standard steel products.

Bright bar material refers to steel or stainless steel that undergoes cold finishing processes such as drawing, peeling, grinding, or polishing. These processes improve:

- Surface smoothness

- Dimensional tolerance

- Mechanical strength

- Machining performance

The most widely used profile is the round bright bar, especially in automotive, construction, and precision engineering applications.

Step-by-Step Stainless Steel Bright Round Bar Manufacturing Procedure

- Raw Material Selection

The process begins with selecting premium stainless steel billets or hot-rolled bars. The quality of raw material directly affects the performance of finished SS bright steels.

Common stainless steel grades include:

- SS 304

- SS 316

- SS 410

- Duplex stainless steels

Reliable manufacturers ensure chemical composition compliance with global standards such as those established by ASTM International.

- Hot Rolling (Initial Formation)

Steel billets are heated at high temperatures and passed through rolling mills to create bars of required approximate size.

This stage provides:

- Structural integrity

- Uniform grain structure

- Base dimensions for further finishing

However, hot rolling leaves scale and surface irregularities, which is why additional finishing is required.

- Surface Cleaning and Pickling

After hot rolling, bars develop oxide scale on the surface.

Manufacturers remove this using:

- Acid pickling

- Shot blasting

- Mechanical descaling

This cleaning stage prepares the material for cold finishing operations and improves surface adhesion during processing.

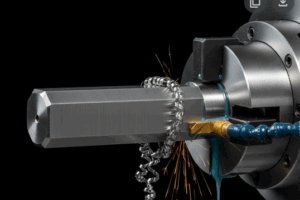

- Cold Drawing Process

Cold drawing is the most important stage in producing bright bar steel.

In this procedure:

- The bar is pulled through a precision die.

- Diameter reduces to the required size.

- Mechanical strength increases due to strain hardening.

Benefits include:

- Tight dimensional tolerances

- Improved straightness

- Smooth surface finish

Cold drawing also enhances machinability, making the bars suitable for CNC manufacturing.

- Straightening Operation

Cold drawing can introduce slight bending stresses.

Special straightening machines are used to:

- Correct alignment

- Improve bar straightness

- Ensure consistent geometry

This step is critical for industries requiring precision components.

- Peeling or Turning

For higher surface quality requirements, manufacturers perform peeling or turning operations.

During this stage:

- A thin outer layer is removed.

- Surface defects are eliminated.

- Diameter uniformity improves.

This produces defect-free round bright bar material suitable for high-performance applications.

- Grinding and Polishing

Depending on customer requirements, bars may undergo grinding or polishing.

Grinding improves:

- Dimensional accuracy

- Surface tolerance

Polishing provides:

- Bright mirror finish

- Enhanced corrosion resistance

- Attractive appearance

This stage gives stainless steel bright bars their signature smooth finish.

- Heat Treatment (If Required)

Some applications require additional mechanical properties.

Heat treatment processes include:

- Annealing

- Solution treatment

- Stress relieving

These processes enhance ductility or hardness depending on grade requirements.

- Cutting and Length Customization

After finishing operations, bars are cut into required commercial or custom lengths using precision cutting equipment.

Manufacturers can provide:

- Standard lengths

- Custom project sizes

- CNC-ready bar dimensions

- Quality Inspection and Testing

A reliable bright bar manufacturer performs strict quality checks before dispatch.

Testing generally includes:

- Chemical composition analysis

- Mechanical testing

- Ultrasonic testing

- Surface inspection

- Dimensional measurement

Manufacturers supplying export markets often follow international quality systems implemented across industrial sectors in India.

Packaging and Dispatch Procedure

After inspection, bars are prepared for transportation.

Packaging methods include:

- Wooden boxes

- Plastic wrapping

- Rust preventive coatings

- Bundle tagging with traceability details

Proper packaging ensures the material reaches customers without damage or contamination.

Why Procedure Matters in Stainless Steel Bright Round Bar Manufacturing

A structured manufacturing process ensures:

- Consistent bright bar material quality

- Superior corrosion resistance

- Longer service life

- Reduced machining time

- High precision engineering performance

Industries such as automotive, oil & gas, aerospace, and heavy fabrication depend heavily on reliable SS bright steels produced through controlled procedures.

Conclusion

The manufacturing procedure of stainless steel bright bars involves multiple precision stages — from raw material inspection to cold drawing, polishing, and quality testing. Choosing an experienced stainless steel bright round bar manufacturer in India ensures access to high-quality bright bar steel that meets demanding industrial standards.

Understanding this process helps buyers select the right supplier and ensures the round bright bar material delivers durability, accuracy, and long-term performance.