Choosing the correct stainless steel grade is a critical step when sourcing a Stainless Steel Square Bar. The right grade directly impacts strength, corrosion resistance, machinability, and long-term performance. For engineers, fabricators, and procurement professionals, understanding grade differences helps ensure efficiency, safety, and cost control.

At Ambica Steels, we manufacture high-quality SS square bars in a wide range of industry-approved grades to meet diverse application requirements. This guide explains how to select the right stainless steel grade for your square bar needs.

Why Stainless Steel Square Bars Grade Selection Is Important?

Each stainless steel grade has a unique chemical composition that affects how the square bar steel performs in real-world conditions. Selecting the wrong grade can result in:

- Premature corrosion

- Poor machinability

- Reduced load-bearing capacity

- Higher maintenance or replacement costs

The correct steel square grade ensures durability, reliability, and optimal performance throughout the product lifecycle.

Key Factors to Consider When Selecting a Grade

Before choosing an SS square bar, evaluate the following:

- Environmental Exposure

- Indoor or outdoor application

- Exposure to moisture, chemicals, or saltwater

- High-temperature or corrosive environments

- Mechanical Requirements

- Strength and hardness

- Wear and impact resistance

- Load-bearing capacity

- Fabrication & Machining Needs

- CNC machining or turning

- Welding requirements

- Surface finish expectations

- Cost vs Long-Term Performance

- Initial material cost

- Maintenance and durability over time

SS Square Bar Grades Offered by Ambica Steels

SS 303 (Excellent Machinability) – SS 303 stainless steel square bars are designed for applications requiring extensive machining.

Key Properties:

- Superior machinability

- Smooth cutting and reduced tool wear

- Moderate corrosion resistance

Typical Applications:

- Precision components

- Fasteners and fittings

- Machined shafts

Best Choice When: Machining efficiency is the top priority.

SS 304 / 304L (Versatile and Widely Used) – SS 304 and 304L square bars are among the most commonly used stainless steel grades across industries.

Key Properties:

- Excellent corrosion resistance

- Good strength and formability

- Easy welding (especially 304L with low carbon content)

Typical Applications:

- Construction and structural frameworks

- Fabrication and general engineering

- Architectural and decorative applications

Best Choice When: You need a reliable, all-purpose stainless steel square bar.

SS 316 / 316L (Superior Corrosion Resistance) – SS 316 and 316L square bars offer enhanced resistance to corrosion, especially in aggressive environments.

Key Properties:

- High resistance to chlorides and chemicals

- Excellent performance in marine and coastal conditions

- 316L offers improved weldability and reduced carbide precipitation

Typical Applications:

- Marine structures

- Chemical and pharmaceutical equipment

- Food processing industries

Best Choice When: Corrosion resistance is critical for long-term performance.

SS 410 (High Strength Martensitic Stainless Steel) – SS 410 square bars provide higher strength and hardness compared to austenitic grades.

Key Properties:

- Good mechanical strength

- Moderate corrosion resistance

- Heat-treatable for improved hardness

Typical Applications:

- Industrial machinery components

- Valves and pump parts

- Automotive and mechanical applications

Best Choice When: Strength and wear resistance are more important than corrosion resistance.

17-4 PH Stainless Steel (High Strength & Performance) – 17-4 PH stainless steel square bars combine high strength with good corrosion resistance.

Key Properties:

- Very high tensile and yield strength

- Excellent fatigue resistance

- Can be precipitation-hardened for specific performance needs

Typical Applications:

- Aerospace components

- Oil & gas equipment

- Heavy-duty machinery and defense applications

Best Choice When: High strength and reliability are essential.

Grade Selection by Application

| Application Area | Recommended Grade |

| CNC machining & precision parts | SS 303 |

| Structural & fabrication work | SS 304 / 304L |

| Marine & chemical environments | SS 316 / 316L |

| High-strength mechanical parts | SS 410 |

| Critical high-performance components | 17-4 PH |

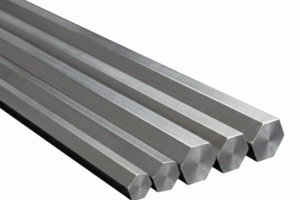

Stainless Steel Square Bar Sizes and Availability

Ambica Steels supplies stainless steel square bars in sizes ranging from 14mm to 42mm, available across all major grades. Our consistent square bar sizes, tight tolerances, and excellent surface finish ensure seamless fabrication and performance.

Why Choose Ambica Steels?

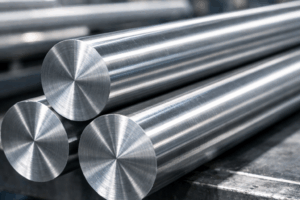

Ambica Steels is a trusted manufacturer and supplier of premium SS square bars and steel square products.

What Sets Us Apart:

- Wide range of grades: 303, 304/304L, 316/316L, 410, 17-4 PH and Many more.

- Precision manufacturing and strict quality control

- Compliance with international standards

- Reliable supply and technical support

- Custom solutions for industrial requirements

Conclusion

Choosing the right stainless steel grade for square bars is essential for performance, durability, and cost efficiency. By understanding application conditions and material properties, buyers can select the ideal square bar steel for their needs.

Whether you require machinability, corrosion resistance, strength, or all-around performance, Ambica Steels delivers high-quality Stainless Steel Square Bars you can trust.