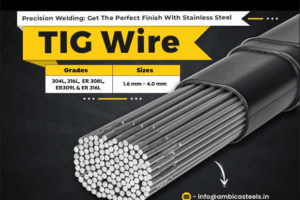

ER308L TIG Welding Wire plays a key role in stainless steel welding. Welders across industries choose it for clean welds, strong joints, and reliable performance. This filler wire works best when welding austenitic stainless steel, especially grades like 304 and 304L.

When projects demand corrosion resistance, smooth finishes, and long service life, ER308L TIG Welding Wire often becomes the first choice. In this blog, we explain when to use it, where it performs best, and why it matters in critical applications.

What Is ER308L TIG Welding Wire

ER308L TIG Welding Wire is a low carbon stainless steel filler wire. The “L” stands for low carbon content, which helps reduce carbide precipitation during welding. As a result, welds resist intergranular corrosion and maintain strength over time.

This wire contains balanced amounts of chromium and nickel. Because of this composition, it matches well with 304 and 304L stainless steel base metals. Welders prefer it for TIG welding due to its stable arc, controlled weld pool, and neat bead appearance.

Key Features of ER308L TIG Welding Wire

- Low Carbon for Better Corrosion Resistance: ER308L TIG Welding Wire limits carbon content to improve corrosion resistance. This feature reduces cracking and improves weld durability, especially in moisture-prone environments.

- Excellent Weld Quality and Finish: The wire supports smooth metal flow during TIG welding. As a result, welders achieve clean beads with minimal spatter. This benefit makes it suitable for visible joints and precision work.

- Strong Mechanical Performance: ER308L TIG Welding Wire delivers good tensile strength and ductility. Therefore, welded joints handle stress, vibration, and temperature changes with ease.

When to Use ER308L TIG Welding Wire

- Welding 304 and 304L Stainless Steel: ER308L TIG Welding Wire works best when welding 304 and 304L stainless steel. These grades appear in many industrial and commercial applications. The wire ensures chemical compatibility and consistent weld performance.

- Projects Requiring Corrosion Resistance: Use ER308L TIG Welding Wire when corrosion resistance matters. The wire performs well in mild chemical exposure, humidity, and food-related environments.

- Precision and Thin Section Welding: TIG welding demands control. ER308L TIG Welding Wire supports steady arcs and precise heat input. Therefore, it suits thin sheets, pipes, and detailed fabrication.

Where ER308L TIG Welding Wire Is Commonly Used

- Food and Beverage Equipment: Manufacturers rely on ER308L TIG Welding Wire for hygienic welds. It supports clean joints that resist corrosion and contamination.

- Pharmaceutical and Chemical Equipment: This wire performs well in controlled chemical environments. As a result, it suits tanks, pipelines, and processing units.

- Architectural and Structural Fabrication: ER308L TIG Welding Wire delivers neat welds for visible structures. Designers value both strength and appearance in such projects.

- Automotive and General Engineering: Automotive components and engineered parts often use 304 stainless steel. ER308L TIG Welding Wire ensures consistent results in these applications.

Benefits of Choosing ER308L TIG Welding Wire

ER308L TIG Welding Wire improves weld life and reduces post-weld issues. It lowers the risk of cracking and corrosion. It also supports easier finishing and inspection. Because of these advantages, many industries trust it for long-term performance.

How Ambica Steel Manufactures ER308L TIG Welding Wire

At Ambica Steel, we manufacture ER308L TIG Welding Wire under strict quality control systems. Our globally certified TIG wires meet international standards for chemistry, strength, and performance.

We use advanced drawing and surface finishing processes to ensure smooth feeding and stable welding arcs. Each batch undergoes rigorous testing to deliver consistent results across applications.

For inquiries, technical support, or timely delivery, contact Ambica Steel. Our team helps you select the right TIG welding wire for your needs and ensures a reliable supply for your projects.