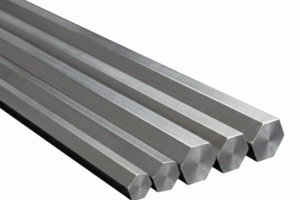

Stainless steel cold drawn flat bars are one of the most versatile products in today’s industrial world. They combine strength, accuracy, and durability. Because of these qualities, the applications of stainless steel flat bars extend across many industries. From automotive to construction, they play a critical role in delivering reliable performance. In this blog, we explore the top seven uses of cold drawn stainless steel flat bars and why they matter.

Applications of Stainless steel flat bars in:

1. Automotive Industry

The automotive industry relies on precise components for safety and performance. Cold drawn flat bars offer tight dimensional accuracy and excellent surface finish. As a result, they are widely used in making fasteners, brackets, and structural parts. These applications of stainless steel flat bars help vehicles last longer while reducing maintenance needs.

2. Construction and Infrastructure

Modern construction requires materials that can withstand pressure and harsh conditions. Stainless steel flat bars provide both strength and corrosion resistance. Builders use them in support structures, frames, and architectural designs. In addition, their smooth finish makes them ideal for exposed applications where aesthetics matter.

3. Energy Sector

Energy production plants demand reliable materials. Power stations, oil refineries, and renewable energy setups all use stainless steel flat bars. They are suitable for turbine parts, pipelines, and structural supports. Among the many applications of stainless steel flat bars, the energy sector shows how they can handle both stress and extreme environments.

4. Engineering and Machinery

Precision engineering requires accuracy. Cold drawn stainless steel flat bars deliver this with consistent size and shape. Machine parts, tools, and heavy equipment use these bars for reliability. Because they resist wear and tear, they reduce downtime and extend machine life. These benefits make them a trusted choice in engineering applications.

5. Shipbuilding and Marine Industry

The marine environment is tough on metals due to constant exposure to water and salt. Stainless steel flat bars solve this challenge with excellent corrosion resistance. They are used in ship hulls, decks, and interior fittings. These applications of stainless steel flat bars ensure strength and long-lasting safety for vessels.

6. Aerospace and Defense

In aerospace, performance and safety are non-negotiable. Flat bars provide structural integrity and precision for components like brackets, frames, and fasteners. Defense applications also rely on their ability to endure stress and resist corrosion. Here, stainless steel flat bars prove their value in some of the most demanding conditions.

7. Consumer Products and Appliances

Beyond heavy industries, stainless steel flat bars also serve everyday needs. Home appliances, furniture, and kitchen equipment often use cold drawn flat bars. Their smooth finish and durability add both function and style. These applications of stainless steel flat bars highlight their role in daily life.

Why Choose Cold Drawn Stainless Steel Flat Bars?

Cold drawn production improves the strength and finish of flat bars compared to hot rolled ones. It gives them higher dimensional accuracy, better mechanical properties, and a clean surface. These qualities make them a preferred choice across industries.

The applications of stainless steel flat bars are vast and growing. From cars to construction, and from energy to everyday products, they deliver unmatched value. If your industry needs precision, durability, and strength, cold drawn stainless steel flat bars are the right choice.

👉 Looking for application-specific flat bars? Get a custom quote from Ambica Steels today