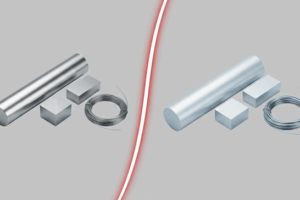

What Is Cold Drawn Stainless Steel?

Cold drawn stainless steel refers to steel that’s processed at room temperature instead of using heat. The metal passes through dies or rollers to reach the desired shape and thickness. This cold working process enhances the metal’s strength and gives it a smooth finish. As a result, cold drawn stainless steel flat bars show higher precision and tighter tolerances than hot-rolled alternatives.

Because it doesn’t require high-temperature treatment, the process reduces energy use. This helps lower carbon emissions and supports eco-friendly production.

Why it Matters?

As the construction industry moves toward greener and more efficient materials, cold drawn stainless steel is becoming a top choice. Its strength, durability, and energy-efficient production process make it a practical solution for modern builders. Unlike traditional steel, it offers a balance of sustainability and performance without compromising on quality.

Benefits:

1. Strength and Durability

The cold drawing process increases the steel’s tensile strength. This means the material can handle more load without deforming. For construction, this is vital. Stronger materials lead to longer-lasting structures that need less maintenance.

2. Sustainable Manufacturing

Cold drawing uses less heat, which cuts energy consumption. This makes cold drawn stainless steel a better environmental option. In addition, stainless steel itself is 100% recyclable. Builders can reuse it at the end of a structure’s life, reducing waste and material costs.

3. Superior Finish and Precision

Cold drawn stainless steel flat bars have a smooth surface and consistent dimensions. This reduces the need for extra machining or polishing. In turn, it saves both time and money during fabrication and installation.

4. Corrosion Resistance

Stainless steel already resists rust and corrosion. The cold drawing process enhances that property by refining the grain structure. This makes it ideal for outdoor or marine environments where moisture is a concern.

Cold Drawn Stainless Steel in Sustainable Construction

Modern architecture focuses on sustainability, efficiency, and lifespan. Cold drawn stainless steel fits all three goals. It helps reduce energy use during production and supports low-maintenance design. Structures built with these flat bars last longer, which means fewer repairs and less material replacement over time.

Additionally, the sleek and polished look of cold drawn bars allows architects to design visually appealing structures without needing extra surface treatments. That adds aesthetic value while keeping the project eco-friendly.

Applications of Cold Drawn Stainless Steel Flat Bars

From bridges to building frames, cold drawn stainless steel flat bars are used across several industries. Common applications include:

- Structural supports in commercial and residential projects

- Reinforcements for bridges, railings, and walkways

- Components in industrial equipment and machinery

- Decorative and architectural elements for modern designs

Their versatility makes them suitable for both functional and design-focused projects.

Why Cold Drawn Stainless Steel Is the Future

The construction world is moving toward materials that reduce environmental impact without losing strength or beauty. Cold drawn stainless steel meets that demand. It’s energy-efficient, recyclable, and long-lasting. With global sustainability goals becoming stricter, builders and architects are turning to materials that align with those standards.

Choosing cold drawn stainless steel flat bars today means investing in the future of construction — one that values both performance and the planet. Contact us for your Cold Drawn Stainless Steel Flat Bars requirements.