Nail wire is the core material used to make nails for construction, furniture, and industrial use. In simple terms, nail wire is drawn steel wire that gets cut and shaped into nails. Because nails hold structures together, the quality of nail wire matters a lot. Today, nail wire plays a key role in safety, strength, and long-term performance across many industries.

In this blog, you will learn what nail wire is, where people use it, the common grades available, and why stainless steel nail wire has become so important.

What Is Nail Wire and How Is It Made

Nail wire starts as a steel rod. Manufacturers clean it first. Then they draw it through dies to reduce its size. This process improves strength and surface finish. After that, the wire reaches specific diameters based on nail size.

Because nail wire must bend without breaking, it needs controlled chemistry. Carbon levels, tensile strength, and surface quality all matter. As a result, good nail wire forms nails that drive easily and hold firmly.

Uses of Nail Wire Across Industries

Nail wire supports many everyday and industrial applications. Since nails vary in size and strength, nail wire must meet different needs.

- Nail Wire in Construction: Builders rely on nail wire for framing, roofing, and formwork. Strong nail wire helps nails resist bending during hammering. Therefore, it improves work speed and site safety.

- Nail Wire in Furniture and Woodwork: Furniture makers use nail wire to create small and medium nails. These nails must look clean and hold joints tightly. For this reason, smooth nail wire with a consistent diameter works best.

- Nail Wire in Packaging and Pallets: Wooden pallets and crates use nails made from nail wire. These nails must hold weight during transport. Because of this, durable nail wire reduces breakage and repair costs.

- Nail Wire in Industrial Applications: Some industries use nail wire for special fasteners and pins. In such cases, controlled strength and corrosion resistance become critical.

Nail Wire Grades and Material Types

Different projects need different nail wire grades. Choosing the right grade improves performance and reduces waste.

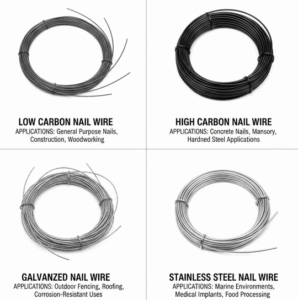

- Low Carbon Nail Wire: Low carbon nail wire is soft and easy to form. It suits common nails for light construction and furniture. Since it bends easily, it reduces tool wear.

- High Carbon Nail Wire: High carbon nail wire offers higher strength. Manufacturers use it for nails that must hold heavy loads. However, it needs careful handling because it is harder.

- Galvanized Nail Wire: Galvanized nail wire has a zinc coating. This coating protects against rust. As a result, it works well for outdoor and humid environments.

- Stainless Steel Nail Wire: Stainless steel nail wire resists rust and corrosion. It performs well in coastal areas, chemical plants, and food-related settings. Because it lasts longer, it lowers replacement costs over time.

Why Stainless Steel Nail Wire Matters Today

Stainless steel nail wire matters more than ever. First, it resists moisture and chemicals. Second, it keeps its strength over long periods. Third, it improves appearance since it does not stain wood.

Moreover, stainless steel nail wire supports green building goals. It lasts longer and reduces waste. Therefore, many builders now prefer it for premium projects.

How to Choose the Right Nail Wire

Choosing nail wire depends on use, environment, and budget. For indoor work, low carbon nail wire often works well. For outdoor or harsh conditions, stainless steel nail wire offers better value.

Also, check wire diameter, tensile strength, and surface finish. These factors help ensure smooth nail production and reliable performance.

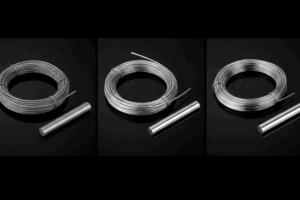

Ambica Steels Stainless Steel Nail Wire

Ambica Steels offers high-quality stainless steel nail wire designed for consistent performance. The wire features uniform diameter, clean surface finish, and strong corrosion resistance. Due to strict quality control, the nail wire ensures smooth nail forming and a long service life.

Ambica Steels stainless steel nail wire suits construction, furniture, and industrial use. It performs well in demanding environments while maintaining strength and appearance. As a result, manufacturers trust it for reliable and long-lasting nails.

By understanding nail wire uses and grades, you can choose better materials. In the long run, quality nail wire saves time, cost, and effort. For bulk stainless steel nail wire purchase, contact Ambica Steels.