A hex bar is a six-sided solid metal bar used in manufacturing, construction, and engineering applications where high strength, easy gripping, and precise machining are required.

Due to its strength, clean shape, and ease of machining, demand for hex bars continues to grow worldwide. If you are searching for reliable information before buying, this guide will help you understand everything clearly, step by step.

At the end, you will also know how to choose the right stainless steel hex bar for your application.

What Is a Hex Bar Used For?

A hex bar is used for:

- Manufacturing bolts, nuts, and fasteners

- Automotive and machinery components

- Oil and gas fittings

- Structural and construction applications

A hex bar is a solid metal bar with six equal sides. This shape allows better grip, easier tightening, and accurate torque transfer. As a result, many industries prefer hex bars over round bars.

In addition, hex bars support precise machining. They reduce material waste and save time during fabrication. Because of these advantages, they work well for both small components and heavy-duty parts.

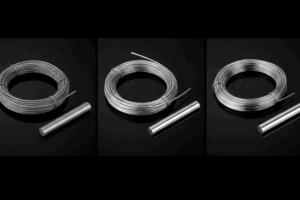

Hex bars come in stainless steel, carbon steel, alloy steel, and other metals. However, stainless steel hex bars remain the most popular choice due to corrosion resistance and long service life.

Why Stainless Steel Hex Bar Is in High Demand

A hex bar made from stainless steel offers multiple benefits. First, it resists rust and corrosion. Second, it performs well under heat and pressure. Third, it needs less maintenance over time.

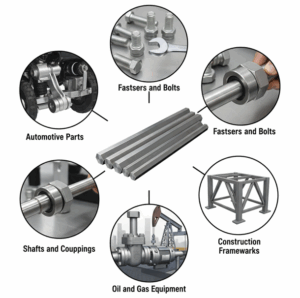

Because of these qualities, stainless steel hex bars are widely used in:

- Automotive parts

- Fasteners and bolts

- Shafts and couplings

- Oil and gas equipment

- Construction frameworks

Moreover, stainless steel maintains its strength without compromising its appearance. This makes it suitable for both industrial and decorative applications.

You can explore a wide range of stainless steel hex bars directly on this product page: 👉 https://www.ambicasteels.com/stainless-steel-products/hex-bars

Which Stainless Steel Grade Is Best for Hex Bar?

The best stainless steel grade for a hex bar depends on the application:

- 304 hex bar for general use

- 316 hex bar for marine and chemical environments

- 310 hex bar for high-temperature applications

Choosing the right grade of hex bar matters. Each grade serves a specific purpose.

Hex Bar Grade 304

Grade 304 is the most commonly used stainless steel hex bar. It offers good corrosion resistance and excellent formability. As a result, it works well for food processing, chemical equipment, and general engineering.

Hex Bar Grade 316

Grade 316 contains molybdenum, which improves corrosion resistance. Therefore, it suits marine, coastal, and chemical environments.

Hex Bar Grade 310 and 321

Grade 310 and Grade 321 handle high temperatures better. They are often used in furnaces, heat exchangers, and pressure vessels.

For official material specifications, you can refer to: 👉 https://www.astm.org/

What Are the Standard Sizes of Hex Bar?

Hex bar sizes are measured across flats. Common sizes range from small precision bars to large industrial sections. Manufacturers supply small sizes for precision components and larger sizes for structural use.

Size Range: 12 mm – 65 mm (0.47 inch- 2.55 inch)

- Small sizes for fasteners

- Medium sizes for shafts and connectors

- Large sizes for heavy-duty machinery

Tolerances of Hex Bar

Tight tolerances ensure accurate machining. Therefore, always check dimensional standards before placing an order. ISO and ASTM standards help maintain consistency worldwide. It is like h10 or h11.

Applications of Hex Bar Across Industries

The hex bar shape offers better load distribution. Because of this, industries rely on it for critical applications.

Hex Bar in Manufacturing

Manufacturers use hex bars for nuts, bolts, and connectors. The shape allows easy gripping and high torque.

Hex Bar in Construction

In construction, hex bars support structural components and anchor systems. They provide strength and stability under stress.

Hex Bar in Oil and Gas

Oil and gas operations need materials that resist pressure and corrosion. Stainless steel hex bars meet both requirements.

How to Choose the Right Hex Bar Supplier

When buying a hex bar, quality matters more than price alone. Therefore, look for a supplier who offers:

- Certified raw materials

- Multiple grades and sizes

- Consistent tolerances

- On-time delivery

Also, check if the supplier provides technical support. This helps you select the right grade for your application.

Ambica Steels offers a wide range of stainless steel hex bars with reliable quality standards. You can review specifications and request a quote directly from their hex bar product page.

Before you buy stainless steel products, understand your application. Then, choose a trusted supplier who meets international standards. This approach saves cost, reduces failure risk, and improves long-term performance.

Choosing the right bar shape affects strength, machining, cost, and performance. While hex bars, round bars, and square bars may look similar, each serves a different purpose. Understanding these differences helps you select the right material for your application.

The main difference lies in shape, grip, machining ease, and load handling.

- A hex bar has six flat sides

- A round bar has a circular cross-section

- A square bar has four equal flat sides

Each shape offers unique advantages depending on how and where it is used.

Best Use Comparison

| Feature | Hex Bar | Round Bar |

|---|---|---|

| Grip | Excellent | Poor |

| Machining | Easier for fasteners | Easier for turning |

| Rolling Risk | None | High |

| Common Uses | Bolts, nuts, shafts | Axles, pins, rods |