In industries where hygiene is critical, material choice matters a lot. An SS round bar plays a key role in meeting strict hygiene and safety standards. From food-processing plants to medical and pharmaceutical equipment, stainless steel round bars support clean, safe, and reliable operations. Because these sectors deal with human health, they demand materials that resist corrosion, clean easily, and last long without contamination risks.

This blog explains why the SS round bar remains the preferred choice for sensitive applications and how it supports hygiene at every stage.

Why SS Round Bar Is Ideal for Hygienic Applications

An SS round bar offers a smooth surface, strong structure, and excellent resistance to rust. These qualities make it suitable for environments that need frequent cleaning and sterilization. Moreover, stainless steel does not react with food, chemicals, or medicines. As a result, it helps maintain purity and safety.

In addition, manufacturers can machine SS round bars easily. This allows precise shapes for equipment parts. Because of this flexibility, industries trust stainless steel for complex and sensitive systems.

SS Round Bar in Food-Processing Equipment

How they Supports Food-Grade Hygiene

Food-processing units must follow strict hygiene rules. An SS round bar helps meet these rules with ease. It does not absorb odors, moisture, or bacteria. Therefore, it keeps food safe during processing.

Also, stainless steel surfaces clean quickly. Workers can wash and sanitize them without damage. This reduces downtime and improves efficiency. Furthermore, the corrosion resistance of an SS round bar prevents rust even in wet or acidic environments.

Common food-grade uses include:

- Conveyor shafts

- Mixing blades

- Support rods

- Cutting and slicing components

Because of these benefits, food manufacturers rely on stainless steel to maintain quality and compliance.

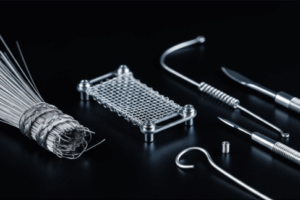

SS Round Bar in Medical Instruments and Devices

Why Medical Tools Depend on it

Medical environments demand the highest level of cleanliness. An SS round bar meets this need through excellent sterilization performance. It withstands heat, steam, and chemical disinfectants without losing strength.

Moreover, stainless steel does not support microbial growth. This helps reduce infection risks. Surgeons and healthcare workers also prefer stainless steel tools because they stay durable after repeated use.

Medical applications include:

- Surgical instruments

- Orthopedic implants

- Diagnostic equipment parts

- Hospital furniture components

As a result, the SS round bar remains essential in modern healthcare systems.

SS Round Bar in Pharmaceutical Equipment

Maintaining Purity with it

Pharmaceutical production requires controlled and contamination-free conditions. An SS round bar supports these requirements by offering chemical stability. It does not react with drugs or active ingredients.

In addition, stainless steel resists harsh cleaning agents used in pharma plants. This allows regular cleaning without surface damage. Also, the smooth finish of an SS round bar prevents particle buildup.

Typical pharmaceutical uses include:

- Reactor shafts

- Mixing rods

- Valve components

- Structural supports

Because of these qualities, pharmaceutical companies trust stainless steel for long-term reliability.

Key Hygienic Benefits

The widespread use of SS round bar in sensitive industries comes from clear advantages:

- Easy to clean and sanitize

- High resistance to corrosion and rust

- Non-reactive with food and chemicals

- Smooth surface that limits bacterial growth

- Strong and long-lasting under stress

Additionally, stainless steel meets global safety and hygiene standards. This makes compliance easier for manufacturers.

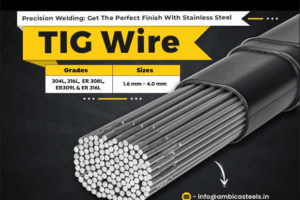

Choosing the Right Grade

Not all stainless steel grades suit every application. For example, SS 304 works well for food and general medical use. However, SS 316 offers better resistance to chemicals and saline environments. Therefore, selecting the right SS round bar grade improves performance and safety.

Ambica Steels SS Round Bar for Hygienic Applications

Ambica Steels offers high-quality SS round bar solutions designed for sensitive industries like food processing, medical equipment, and pharmaceuticals. Each SS round bar from Ambica Steels meets strict quality and hygiene standards. The bars feature a smooth finish, accurate dimensions, and strong corrosion resistance. Because of consistent quality control, Ambica Steels SS round bars support safe manufacturing and long service life. Moreover, the company supplies stainless steel grades suitable for food-grade and medical use, ensuring reliability across critical applications.

If you are looking for a reliable SS round bar supplier for hygienic and sensitive applications, choose Ambica Steels. Contact the team today to discuss your requirements and get expert guidance on the right stainless steel solution for your industry.