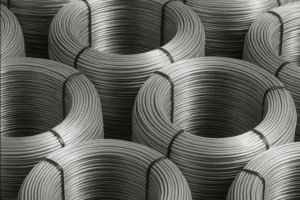

Stainless steel wire plays a vital role in modern industry. You can find it in construction sites, factories, hospitals, and even in everyday products. Its strength, corrosion resistance, and flexibility make it one of the most trusted materials today. However, its journey started more than a century ago. Understanding the history of stainless steel wire helps explain why it remains so valuable across industries.

The Invention of Stainless Steel Wire and Stainless Steel

The history of stainless steel wire begins with the discovery of stainless steel itself. In 1913, English metallurgist Harry Brearley searched for a better metal for gun barrels. During his experiments, he added chromium to molten iron. As a result, he created a steel that resisted rust and stains.

This discovery changed metal production forever. Unlike carbon steel, stainless steel did not corrode easily. Because of this, manufacturers quickly recognized its potential. Soon after, producers began drawing stainless steel into wire form. This process opened the door to many new uses.

Early Uses of Stainless Steel Wire in Industry

In the early years, stainless steel wire mainly served military and industrial needs. During World War I, aircraft manufacturers used stainless steel wire for cables and fasteners. The wire offered high strength without adding much weight. At the same time, it performed well in harsh weather.

Meanwhile, industries adopted stainless steel wire mesh for filtration and sieving. It resisted chemicals and heat better than other metals. Therefore, food processing and chemical plants started using it more often. These early applications proved the wire’s durability and reliability.

Industrial Growth of Stainless Steel Wire in the 1930s and 1940s

As industries grew, so did the demand for stainless steel wire. During the 1930s and 1940s, manufacturers expanded its use across many sectors. Chemical plants relied on it because it resisted acids and moisture. Food producers preferred it since it met hygiene standards.

At the same time, marine industries used stainless steel wire for ropes and fittings. Saltwater environments damaged ordinary metals quickly. However, stainless steel wire lasted much longer. Because of this advantage, producers invested in better wire drawing methods and new alloy blends.

Post-War Advancements

After World War II, global reconstruction increased the need for strong materials. Stainless steel wire met this demand perfectly. Builders used it in reinforced structures, fencing, and infrastructure projects. Household goods also began to feature stainless steel wire components.

During this period, manufacturing technology improved. Companies achieved better control over wire diameter and surface finish. As a result, quality became more consistent. These improvements helped stainless steel wire enter mass production markets.

Evolution of Grades and Types

Over time, engineers developed different grades of stainless steel wire to meet specific needs. Each type offered unique properties.

- Austenitic Stainless: These wire provides excellent corrosion resistance and flexibility. It works well in food processing, medical tools, and chemical plants.

- Ferritic Stainless: These wire offers good strength and resistance to stress corrosion. Manufacturers often use it in automotive and appliance parts.

- Martensitic Stainless: These wire delivers high hardness and strength. It suits springs, cutting tools, and mechanical components.

Modern Applications of Stainless Steel Wire

Today, stainless steel wire supports countless industries. In the automotive sector, manufacturers use it for springs, cables, and fasteners. These parts must handle stress, heat, and vibration.

In healthcare, stainless steel wire plays a critical role. Surgeons rely on it for implants, surgical tools, and orthodontic devices. It remains safe during sterilization and works well inside the human body.

Architecture and design also benefit from stainless steel wire. Designers use it for railings, facades, and decorative features. Its clean appearance and long life make it a popular choice. Additionally, renewable energy and electronics industries continue to find new uses for it.

The Lasting Impact of Stainless Steel Wire

The history of stainless steel wire shows how one discovery transformed many industries. From its accidental invention to its modern applications, it continues to prove its value. Its strength, corrosion resistance, and adaptability set it apart from other materials.

As technology advances, stainless steel wire will likely gain even more uses. For this reason, it remains a key material in both traditional and emerging industries. Its journey from innovation to necessity highlights its lasting importance in the modern world.