In modern machining, precision, speed, and efficiency drive success. That’s why more manufacturers

now rely on ASMAX Grades from Ambica Steels. Designed for high machinability, these stainless steels

deliver fast performance and reliable results. In this blog, we’ll explore what ASMAX is, its standout

features, major benefits, and how Ambica Steels supports your success with ASMAX Grades.

What is ASMAX?

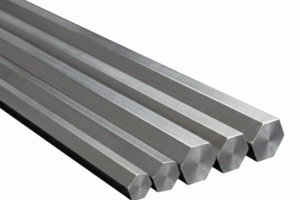

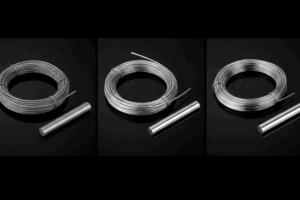

ASMAX Grades are not just high-quality steels—they are solutions for advanced machining needs.

Developed by Ambica Steels, these grades are built for high-speed and complex machining applications.

ASMAX stands for Ambica Steels Machinability Excellence.

Unlike standard stainless steels, ASMAX Grades help manufacturers:

- Reduce machining time

- Minimize tool wear

- Lower operational costs

- Improve part quality

Thanks to their advanced design, these grades ensure smoother production, less downtime, and

consistent output. Industries such as automotive, aerospace, and precision components have already

adopted ASMAX Grades for their critical operations.

Key Features of ASMAX Grades

ASMAX Grades offer unique technical advantages that boost machining performance. Here are the top

features:

- Enhanced Sulfur Content: Improves chip formation and breakability

- Tight Tolerances: Enables excellent dimensional control

- Superior Surface Finish: Reduces need for secondary processing

- Consistent Quality: Maintains uniform performance across batches

- High Yield Strength: Suitable for both structural and functional parts

Each feature helps you produce more, waste less, and meet quality standards with ease.

Key Benefits of ASMAX Grades

Switching to ASMAX Grades gives your production line several advantages. Let’s break them down:

- Faster Machining Cycles – Cut production time significantly

- Lower Tool Costs – Reduce wear and extend tool life

- Improved Surface Finish – Achieve ready-to-use parts

- Higher Productivity – More output in less time

- Reliable Operations – Minimize unexpected delays or downtime

With these benefits, ASMAX Grades help businesses save costs and scale operations without sacrificing

quality.

Why Choose ASMAX Grades?

Traditional stainless steels, such as 304 or 416, often bring challenges. These include tough chip

formation and high tool wear, especially in high-speed or CNC operations. That’s where ASMAX Grades

excel.

- Excellent Machinability: Thanks to controlled inclusions and balanced chemistry, ASMAX

provides excellent chip control. It allows smoother cuts and stable machining even at high

speeds. - Extended Tool Life: Reduced heat and friction during cutting help tools last longer. This means

fewer tool changes and less downtime. - Superior Surface Finish: Smooth cutting action creates cleaner surfaces. In many cases, no

secondary polishing or finishing is required.

Whether youre machining simple parts or complex profiles, ASMAX Grades give you better results in

less time. That’s why they’re the preferred choice for forward-thinking manufacturers.

How Ambica Steels Can Help You

At Ambica Steels, we don’t just supply steel—we deliver machining solutions. Our ASMAX Grades come

from decades of R&D, global manufacturing expertise, and a deep understanding of industry challenges.

When you choose Ambica Steels, you get:

- Custom-Made Solutions for your exact machining requirements

- Fast and Reliable Supply Chains to keep your operations running

- Technical Support from experienced metallurgists and engineers

- Compliance with Global Standards for quality and sustainability

We aim to help you boost performance, lower costs, and achieve operational excellence.

Upgrade your production. Choose ASMAX Grades. Lead with Ambica Steels.