Choosing the right materials is vital in modern construction and engineering. One material that stands out is the SS angle bar. Known for its strength, flexibility, and corrosion resistance, the SS angle bar plays a key role in buildings, bridges, and industrial structures.

From architectural design to heavy-duty infrastructure, SS angle bars provide both support and style. Let’s explore why these “L”-shaped bars are the hidden champions of today’s structural world.

What Is an SS Angle Bar?

An SS angle bar is a stainless steel bar shaped like the letter “L”. It comes with either equal or unequal sides. Manufacturers create these bars using strong stainless steel grades like SS 304 and SS 316. These grades offer great durability and rust resistance.

Thanks to its shape and strength, the SS angle bar is used in many construction and industrial tasks. It is easy to cut, drill, weld, and assemble.

Key Benefits of SS Angle Bar

-

High Strength with Low Weight

SS angle bars offer great support while keeping weight low. This makes them perfect for load-bearing structures.

-

Excellent Corrosion Resistance

Stainless steel, especially grade 316, resists rust and harsh weather. This makes SS angle bars ideal for coastal, chemical, or outdoor projects.

-

Easy to Use and Modify

Their simple “L” shape makes SS angle bars easy to handle. They can be joined, shaped, and installed with common tools.

-

Long Lifespan with Low Maintenance

Stainless steel does not need paint or extra coating. This reduces upkeep and increases long-term value.

Common Uses of SS Angle Bar in Construction

-

Building Frames and Structures

SS angle bars are used to build the frames of buildings, towers, and industrial sheds. They distribute weight well and improve safety.

-

Concrete Reinforcement

Engineers use SS angle bars inside concrete beams, columns, and slabs. These bars add tensile strength and boost stability.

-

Roofing and Cladding Support

In roofing systems, SS angle bars act as a strong base. Their corrosion resistance helps them last long, even under tough weather.

-

Platforms, Ladders, and Stairs

In factories and commercial areas, SS angle bars are used to build safe platforms, staircases, and ladders.

-

Racking and Storage Systems

Warehouses use SS angle bars to make heavy-duty shelves and racks. These systems support large weights and last for years.

-

Modern Architectural Features

SS angle bars also add style. They are used in handrails, window trims, and building façades to give a modern look while adding strength.

Key Factors for Selection SS Angle Bars

Choosing the right SS angle bar is essential for the success and safety of any structural or industrial project. With so many options available, making an informed choice requires understanding the key factors that impact performance, durability, and cost. Whether you’re designing a building frame or a storage rack, selecting the correct SS angle bar ensures structural integrity and long-term value.

-

Grade of Stainless Steel

The grade is the most important factor when selecting an SS angle bar. Different grades offer various levels of strength, corrosion resistance, and workability.

-

- SS 304: This is the most common grade. It’s ideal for general construction due to its good corrosion resistance and ease of welding and forming.

- SS 316: This grade has added molybdenum, offering higher resistance to chlorides and chemicals. It’s perfect for marine and chemical environments.

Tip: Choose SS 316 for coastal or industrial areas with high exposure to harsh elements.

-

Size and Thickness

SS angle bars come in various sizes, including equal and unequal leg dimensions. The thickness of the bar directly affects its load-bearing ability.

-

- Equal leg angle bars: Same length on both sides, ideal for symmetrical support.

- Unequal leg angle bars: Used where design constraints or stress direction varies.

Tip: Match the size and thickness to the expected load and design needs to avoid over- or under-engineering.

-

Corrosion Resistance

Depending on the environment, corrosion can become a serious issue. For projects exposed to moisture, chemicals, or salt, selecting a highly resistant grade like SS 316 is crucial.

Tip: For indoor or dry applications, SS 304 is usually sufficient. For outdoor or marine settings, go for SS 316 or higher.

-

Surface Finish

The surface finish not only affects the appearance but also the corrosion resistance and maintenance requirements.

-

- HRAP (Hot Rolled Annealed and Pickled): Matte finish, suitable for structural applications.

- Polished Finish: Used where aesthetics are important, such as handrails and architectural trim.

Tip: Use polished finishes for exposed architectural elements, and HRAP for hidden structural components.

-

Fabrication and Workability

Stainless steel angle bars need to be cut, welded, and drilled during fabrication. Some grades and thicknesses are easier to work with than others.

Tip: For projects requiring lots of on-site modifications, SS 304 offers better formability and ease of machining.

-

Compliance and Standards

Ensure that the SS angle bar you select complies with international standards such as ASTM A484 or EN 10056. These standards define mechanical properties, tolerances, and surface quality.

Tip: Always request certification or test reports from your supplier to verify compliance.

-

Supplier Reliability

Choosing a trusted SS angle bar supplier ensures consistent quality, timely delivery, and post-sale support. Look for suppliers with a strong track record and certified manufacturing processes.

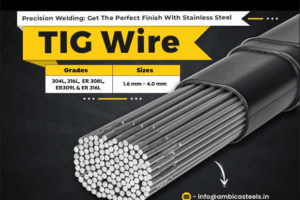

Tip: Companies like Ambica Steels offer solution-annealed angle bars with accurate tolerances and premium grades like AISI 304L and 316L.

Why Choose Ambica Steels for SS Angle Bars?

Ambica Steels supplies high-quality SS angle bars that meet global standards. Our products come in lengths from 2 to 6 meters (8 to 20 feet) and meet ASTM A 484 and EN 10056 tolerances. Each bar has a clean HRAP surface and is solution-annealed for better strength.

We offer premium grades such as:

- AISI 304L / DIN 1.4307

- AISI 316L / DIN 1.4404

Whether you are working on a skyscraper or a factory floor, our SS angle bars will meet your performance needs.

Ready to buy?

Visit our Angle Bar Products Page or email us at dm@ambicasteels.com for more info.