Eddy Current Testing is changing how we inspect stainless steel long bars. This method finds surface cracks quickly and accurately. It helps buyers get better products with fewer defects. With growing demand for quality, this technology is now a must in steel manufacturing.

Let’s explore what Eddy Current Testing is, how it works, its benefits, and why it matters to stainless steel buyers.

What is Eddy Current Testing?

Eddy Current Testing is a non-destructive method used to inspect metal surfaces. It uses electromagnetic fields to find flaws like cracks or pits. These currents change when they hit a defect. This change helps inspectors find problems without damaging the product.

The method works best on conductive materials like stainless steel. It is fast, reliable, and can inspect 100% of the surface.

How Eddy Current Testing is Used in Stainless Steel Bars

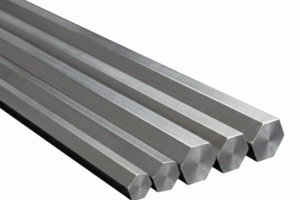

Manufacturers use Eddy Current Testing to check long stainless steel bars. These bars are used in many industries — from automotive to medical. The testing machine runs along the bar’s surface. It checks for defects such as:

- Surface cracks

- Pits

- Inclusions

- Scratches

Modern machines can check each bar quickly. The results are instant. This means bad bars are sorted out fast, and good bars move to the next step.

Benefits of Eddy Current Testing

Eddy Current Testing has many clear benefits:

- Non-Destructive: The test does not harm the metal. You get full inspection without waste.

- Fast and Efficient: The process is quick. It fits well in high-speed production lines.

- Accurate: The test finds even small defects. You can trust the results.

- Lower Costs: Less waste and fewer returns mean lower costs for both makers and buyers.

- Better Quality: Each bar meets strict quality checks. This builds trust between makers and buyers.

Why Stainless Steel Buyers Should Care

If you are buying stainless steel bars, Eddy Current Testing gives peace of mind. Here’s how it helps:

- You get bars that are defect-free

- Less chance of failure in your end use

- More trust in the supplier

- Better performance in your product

- Lower risk of delays or recalls

Industries like aerospace, defense, medical, and oil & gas demand perfect material. This testing method helps meet that high bar.

Ambica Steels Invests in Eddy Current Testing

To serve customers better, Ambica Steels has upgraded its quality control systems. We now use the Dr. Foerster Eddy Current Testing Machine for all stainless steel long bars.

This smart move boosts our ability to deliver bars that meet global standards. It shows our promise to give you strong, reliable, and top-quality stainless steel — every time.

With this new system, our bars are cleaner, stronger, and safer. It’s another step in our journey to offer unmatched value to our customers.

#EddyCurrentTesting #StainlessSteel #AmbicaSteels #QualityControl #SteelInspection #SurfaceCrackDetection