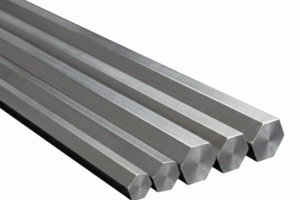

The automotive industry is a landscape in which durability, safety, and performance are paramount amid constant innovation. The stainless steel hex bar is also among all of the necessary raw materials for contribution to this progress. Also known as a hex bar, hex rod, or hexagon rod, this six-sided steel product combines mechanical strength, corrosion resistance, with machinability perfectly—making it a critical component in automotive design and manufacturing.

This stainless steel hexagon bar offers raw material but also precisely engineers solutions to applications needing high performance. In that sector, tolerances must be fairly tight, and reliability simply cannot be negotiated at all. In that sector, hex bars can offer some advantages.

- Ideal for reducing overall vehicle weight because of Extraordinary Strength-to-Weight Ratio without compromising strength.

- It resists contact with water, compounds, and deicers for rust prevention.

- Superior Machinability assures production at high speed. It tightly controls dimensions.

- Reduced wear results from Long-Term Durability. This happens throughout the vehicle’s life.

Because hex bars are indeed machined, bolts, nuts, and even screws maintain integrity that is structural when under stress.

- High tensile strength, stainless steel hex bars are perfect to use for torsion-resistant applications. This makes for them an ideal choice for drive shafts as well as axles.

- Engine Components: Hex rods are often used in valves as well as timing parts also they are used in other high-heat zones.

- Suspension Systems: Precision-fit hexagon rods contribute to mounting points, brackets, and control arms.

- Fuel & Exhaust Systems: Grade 316 stainless steel hex bars offer resistance to corrosive fuels and exhaust gases.

Common Stainless Steel Grades Used in Stainless Steel Hex Bar

| Grade | Properties | Application |

| 304/304L | General purpose, corrosion-esistant | Body panels, bolts, brackets |

| 316/316L | Superior corrosion resistance | Fuel system, exhaust fittings |

| 303 | Excellent machinability | Screws, bushings, small fittings |

| 410/416 | Heat-treatable, high strength | Shafts, gears, wear-resistant parts |

How Stainless Steel Hex Bar Improve Automotive Manufacturing

- Precision Machining: The uniform hexagonal shape allows for quick chucking and accurate machining on CNC lathes and mills.

- Reduced Waste: Dimensional accuracy leads to better material utilization and cost savings.Improved Assembly Fit: Hexagon-shaped parts integrate seamlessly into systems designed for torque tools and spanners.

Ambica Steels: A Trusted Supplier for Automotive-Grade Stainless Steel Hex Bar

When it comes to automotive applications, consistency and quality are critical. Ambica Steels Limited is a leading global manufacturer of stainless steel hex bars, providing high-performance materials to OEMs and Tier-1 suppliers worldwide.

Why Automotive Engineers Choose Ambica Steels:

- Over 50 years of metallurgical expertise

- ISO 9001, IATF 16949, PED, and EN 10204-certified products

- Custom cut-to-length hex rods for high-volume production lines

- Exporting to over 60 countries including Germany, USA, and Japan

- Manufacturing Capabilities:

- Size Range: 12mm to 46mm

- Finish Options: Bright drawn, peeled, centerless ground

- Tolerances: As per ASTM A484, EN 10060, and customer-specific drawings

Whether you need custom sizes, tight tolerances, or specific finishes, we have the expertise and capabilities to deliver. Contact us today by filling out our inquiry form or send your requirements directly to dm@ambicasteels.com—our team is ready to assist you with the right solution.