Introduction to 303, 304, and 316 Stainless Steel Grades

Stainless steel is one of the most versatile and robust materials used across industries today. Among the many stainless steel grades available, 303, 304, and 316 stainless steel grades are the most widely used due to their distinct properties and performance characteristics.

At Ambica Steel, we manufacture high-quality stainless steel tailored to diverse industrial requirements. This blog explains the key differences between 303, 304, and 316, helping you make an informed material selection based on application, environment, and performance needs.

Importance of Choosing the Right 303, 304, and 316 Grades

Material selection plays a critical role in performance, durability, and safety. For example, chemical processing equipment requires stainless steel with high resistance to corrosive chemicals, while marine applications demand materials that can withstand saltwater exposure.

Understanding the differences between 303, 304, and 316 stainless steel ensures the right balance of strength, corrosion resistance, machinability, and cost for each application.

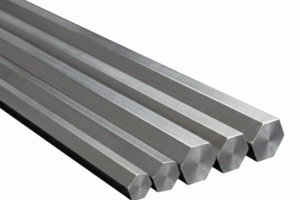

Overview of Common 303, 304, and 316 Stainless Steel Grades

The 303, 304, and 316 grades each offer unique benefits:

- 303 stainless steel is preferred for machining and precision components

- 304 stainless steel is the most versatile and widely used grade

- 316 stainless steel provides superior corrosion resistance in harsh environments

Each grade serves a specific industrial purpose based on its composition and properties.

Chemical Composition of 303, 304, and 316 Stainless Steel

303 Stainless Steel Composition

- Chromium: 17.0%–19.0%

- Nickel: 8.0%–10.0%

- Sulfur: 0.15%–0.35%

- Carbon: Up to 0.15%

- Iron: Balance

The added sulfur improves machinability, making 303 ideal for machining-intensive applications.

304 Stainless Steel Composition

- Chromium: 18.0%–20.0%

- Nickel: 8.0%–10.5%

- Carbon: Up to 0.08%

- Manganese: Up to 2.0%

- Iron: Balance

304 stainless steel offers an excellent balance of corrosion resistance, strength, and affordability.

316 Stainless Steel Composition

- Chromium: 16.0%–18.0%

- Nickel: 10.0%–14.0%

- Molybdenum: 2.0%–3.0%

- Carbon: Up to 0.08%

- Iron: Balance

Molybdenum significantly enhances corrosion resistance, especially in saltwater and chemical environments.

Mechanical Properties of 303, 304, and 316 Stainless Steel

Strength and Hardness Comparison

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) |

|---|---|---|---|

| 303 | 600 | 240 | 190 |

| 304 | 620 | 250 | 187 |

| 316 | 580 | 290 | 217 |

While 304 and 316 offer higher overall strength, 316 provides better hardness in demanding conditions.

Ductility and Toughness in 303, 304, and 316

- 303: Moderate ductility due to sulfur content, reduced toughness

- 304: High ductility and excellent toughness, suitable for forming and welding

- 316: Comparable ductility to 304 with superior toughness in harsh environments

Corrosion Resistance of 303, 304, and 316 Stainless Steel

- 303 Stainless Steel performs well in mild environments but is unsuitable for marine or aggressive conditions

- 304 Stainless Steel offers excellent corrosion resistance in most industrial and household environments

- 316 Stainless Steel excels in saltwater, chemical processing, and highly corrosive conditions

Weldability and Machinability of 303, 304, and 316

Weldability

- 303: Poor weldability due to sulfur

- 304: Excellent weldability

- 316: Excellent weldability with improved corrosion resistance at weld joints

Machinability

- 303: Best machinability

- 304: Moderate machinability

- 316: More challenging to machine but offers superior durability

Temperature Resistance of 303, 304, and 316 Stainless Steel

- 303: Up to 870°C (intermittent)

- 304: Up to 925°C

- 316: Up to 1200°C

All three grades perform well at cryogenic temperatures, with 304 and 316 showing better toughness.

Applications of 303, 304, and 316 Stainless Steel

| Grade | Common Applications |

|---|---|

| 303 | Bolts, nuts, gears, precision machined parts |

| 304 | Kitchen equipment, architectural structures, automotive parts |

| 316 | Marine equipment, pharmaceutical tools, chemical processing, medical implants |

Cost Considerations for 303, 304, and 316

- 303: Higher cost due to sulfur addition, ideal for precision machining

- 304: Most cost-effective and versatile

- 316: Highest initial cost but offers long-term value in corrosive environments

Environmental Impact of 303, 304, and 316 Stainless Steel

All 303, 304, and 316 stainless steel grades are 100 percent recyclable. Higher corrosion resistance in 304 and 316 increases lifespan, reducing material replacement and environmental impact.

Choosing the Right 303, 304, and 316 Stainless Steel Grade

Each of the 303, 304, and 316 stainless steel grades serves a specific purpose. Grade 303 is best for machinability, 304 suits general-purpose applications, and 316 is the preferred choice for corrosive and marine environments.

At Ambica Steel, we ensure consistent quality and reliable performance across all stainless steel grades. Contact us to discuss your application needs and get the right material solution.